Fun watch related to your pic https://youtu.be/udNXMAflbU8

Fuck yeah, technology connections.

I knew it would be before I clicked. Alec is great!

summary: the holes are almost never (purposely) used to secure the plug in the socket. it is often just for manufacturing reasons (but not always, as in this case). it is included in the specifications as an optional feature, so that the holes are not made too big, or in the wrong place.

I’m curious why he doesn’t talk about all the patents that specify locking as a feature. Even modern patents reference the features of older ones in their designs if they use them.

He used all modern plugs you would find on houses in 2000+, of course none of them lock the old way. Go grab some from the 20s and 30s.

In the cheap one, we have two perfectly flat brass pieces pressing against each other.

I’ll bet you any ammount you want, that’s not brass. It’s iron with brass coating.

Is a brass coating not, technically, a flat brass piece pressed against another?

LOGIC’D

I knew exactly what video you linked before I clicked it.

I am very familiar with Alec. Love that channel.

There is no finite life span on any connector.

You obviously haven’t used a Cannon or a Neutrik made XLR connector. I have one from the 1970s, it still works like a chram.

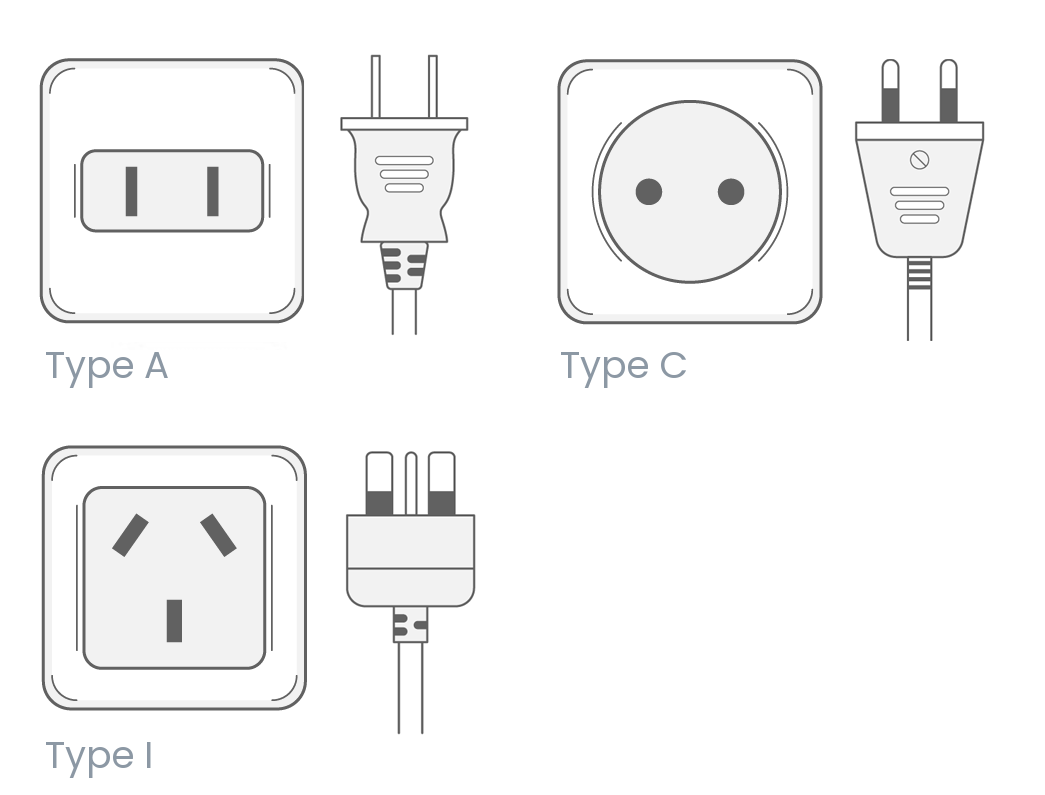

Also, take a look at some of the Type F power plugs. If that’s not robust, IDK what is.

I’m not American, but I’ve lived a few years in the US. I find it very interesting that the US invented the electric infrastructure that we use today, but they really screwed up a few things. Firstly, the connectors are far too unsafe. They are flimsy and have no protection from electrocution. Secondly, by using 120V as the main voltage, you need more current to do the same amount of work as a 240V system. Thay means thicker wires, more stress on the plugs, and greater fire hazards.

Shuko plugs FTW

Common misconception about the voltage though, the US does have a 240v system (well in houses, some places have three phase power which gets weird). The breakers can be wired to give 120v or 240v. The large appliances like driers or electric car chargers and things that do need a large ampunt of current get wired up for that. It’s really only a slightly slower electric kettle to deal with as a minor inconvenience. Or maybe if you wanted an absolutely enormous electric space heater or something, but those are dangerous as it is. Not a lot of things used need more than the 1800 watt maximum. As far as I can tell it’s just a relic of history, Edison ran his generators at about 110v originally and that’s the voltage original light bulb filaments wanted and higher voltage filaments weren’t used until after the US had already been electrifying to a good extent. Theoretically 120v might be a little safer from a getting shocked standpoint, but electrocutions are pretty rare as it is, just a historical artifact and not a conscious design choice as far as I can tell (and yes, volts do matter too, not just amps. Especially if what’s being shocked has very high resistance, like human skin).

Technology connections has a fun video on this too in addition to the plug hole video someone linked elsewhere: https://youtu.be/jMmUoZh3Hq4?si=4a1SCYOZUy-1z2h_

I’ve used electric kettles in the US and Europe and they’re barely slower. I think the difference is overstated. It’s often used as the reason that fewer Americans have kettles but I think the real reason is just that Americans drink fewer hot beverages other than coffee, and most people have a machine for that.

While 120v is safer for shocks I think the greater safety reason for 240 is lower fire risk which is more common and dangerous that shocks in either system.

just get a hot water tap. boiling water on demand for serious tea consumption.

Great for french press too.

The induction range will make the electric kettle moot anyways.

It’s not surprising. If you’re first to adopt something by the time you realize how it could be improved you’re locked into what you did. It happens with all kinds of early adoption. I noticed it a lot in Japan which picks up tech really quickly but as a result has been left with a bunch of crufty old systems. Like they were way ahead on contactless payment, but now they have a bunch of complex and confusion payment systems and lots of them don’t support credit cards while the rest of the world just has contactless credit cards.

yeah but it looks like a funny face!

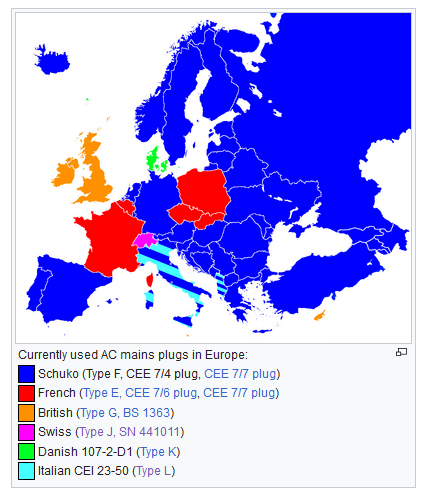

I didn’t know that schuko plugs are the norm for most Europe countries, I thought it was a German thing

https://en.wikipedia.org/wiki/SchukoAlso the french system is compatible with Schuko, so that makes it even more universal.

Yeah I don’t know why we don’t make the switch in France as it wouldn’t be that much of a change

It would be from a financial standpoint. Changing a standard this widely implemented is very costly.

Why change it if they’re compatible anyways? Most devices in the eu are designed to accomodate both, its just a question of the earth pin being different.

I’ve travelled all across europe, coming from a country with the french style outlets. I never had any problems connecting anything except for Switzerland and Italy, because they stuck to their own (inferior) standard thats not compatible with anything else.

The smaller devices like chargers and small lamps have a euro plug that can plug in schucko, danish, italian, swiss, french (but not british)

You’re right, I forgot about that. But good luck plugging your laptop or hair dryer in without some janky adapter.

A laptop you can plug in all of Europe. But a hairdryer you cant because (at least mine) uses a schucko plug (but without ground so wtf)

Many people from other countries fret about the unsafe plugs in the US. They of course do not have the same level of safety, but it also doesn’t appear to matter. I have never been shocked inserting or removing a US plug. I don’t know and haven’t heard of anyone who has. People do get shocked, but for other reasons.

I have, but I was a child and very much not plugging it in the right way. It was in a very cramped space I couldn’t see, and dumbass me thought holding the metal would give me better control. It did, I made it into the plug.

Ok, so there are people out there doing it.

Did you die? I wonder about the truth behind the idea that getting shocked with 120v is less likely/hazardous than double that

I did, in fact die. God is real, but it’s complicated. Eat your vegetables. Your mom was always proud.

As a kid I used a metal tool to cut a live wire 220v-240v wire and besides getting scared by the jolt I was fine. Probably because the protection circuits kicked in

As an idiot, I’ve gotten shocked by 120v multiple times and 240v once. That hurt a lot more. Hopefully I have survived long enough so far to be less of an idiot

The one time I’ve had an issue with our plugs (that would have been solved by something like the British plug design) was when I wasn’t paying attention to a remote antenna resting on top of a loose plug. Accidentally caused a short that melted that little bit of wire but nothing else happened. Just had a black spot on that outlet from then onward.

I have shocked myself on one once but just like with the other person replying that was as a child and felt more like a learning experience to not mess with outlets.

This is exactly why I like having “upside down” US plugs where the ground pin is on top. If there’s a ground pin in the plug, it prevents pennies and paperclips from falling onto the hot and neutral pins. Unfortunately, this isn’t as common because 1. Some contractors beleive it’s illegal, 2. Many wall wart adapters and lay flat plugs assume the receptacle goes ground pin down, and 3. It doesn’t look like a shocked face.

If your plug is not plugged in completely flush with the wall power point so a penny (or etc) can fit between the plug and powerpoint and yet the power can get through, then there is something very wrong.

It happens all the time across the country. Crusty metal debris and Light-pressure low-surface area contact can cause a hot burning short before tripping the breaker. The contact is also inconsistent as it melts and breaks contact, further delaying the breaker trip before it falls back down. There’s literally a tiktok challenge with plenty of burnt outlets, plugs, and pennies available for your viewing pleasure

Yet more proof that the US is foreign as hell.

Type J > Shuko

Type J is safe and a better implementation. I don’t know why the EU didn’t choose type J as a standard.

It cant plug both ways

I think the distinction is we don’t use general purpose 240v receptacles. We only use them as dedicated circuits for built in major appliances. Historically that was sufficient.

We also don’t really use 20a outlets. I don’t know why, especially now that we require 20a circuits in a few places, but you rarely see 20a outlets or appliances with 20a plugs, even though a lot of small appliances could benefit from a little extra power

So is there really a need? Electric kettles are a perfect scenario but what else? Most other use cases for 240v are “built in” appliances not likely to move (welder, air conditioner, laundry, range, etc). Space heaters and hot plates are already dangerous enough that allowing double the current seems like a hazard

Space heaters and hot plates are already dangerous enough that allowing double the current seems like a hazard

You’d require half the current for the same wattage at 240v. At most, it’s the same 15a max, with double the voltage.

Tbh I think I’d rather achieve the same heat output by running them at 240v using less current instead of 110v and pulling as much current as possible/permitted (15a).

Insulation is cheaper than actual conductors too. Higher voltage and lower current means thinner conductors with more insulation to protect them. You’d also remove complexity and thus cost by only needing one voltage. No need for a split phase supply.

I think 240v would be a better option. 🇨🇦

u fool if the plugs functioned consistently and were made intelligently that might cost extra money and would DEMOLISH the rich peoples pockets we cant have that. who’s gonna profit off my taxes?

On your first point, the plugs have improved quite a lot in the last 10 or so years. Still not enough compared to most other Western standards, and it’s taken to long. But they have improved.

…Just in time for USB plugs and sockets to start taking off. Though I’m not sure how big a deal those are when it comes to safety.

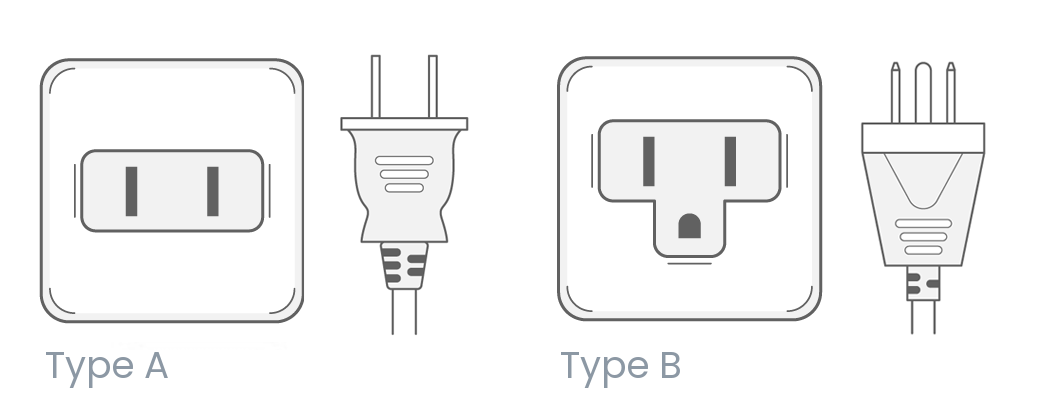

The holes are only for manufacturability.

Older receptacles had a design that would hug the holes to hold the plug in place. It’s a holdover for people with older houses.

I think this fact is actually a myth, the holes are for manufacturing as stated previously.

Not exactly a myth, but likely never used for retention purposes as was originally intended. See more here: https://electronics.stackexchange.com/questions/11495/nema-5-15p-blade-holes

Older receptacles and even modern receptacles and cords do still make use of their holes.

It’s why if the holes are included there is specs they must follow.

This plug makes use of the holes for a solid mechanical connection that will only be removed when you pull on the collar to remove the pin that goes through the holes.

If it’s for manufacturing why are some made without them?

Theres patents out there, I don’t know why technology connection did his own experiments on modern plugs instead of a modicum of research about receptacles.

Not exactly sure, I think it’s just one of those things were we “people” have gotten so used to the design and how it’s supposed to look, that even if it’s not needed we keep doing it.

Since multiple companies manufacturer plugs and connections, some manufacturers may not need the holes as a part of the assembly process. Other may opt not to add them as they do not have a purpose (other then how we perceive a north america plug is supposed to look like).

Funny story, almost all standard north america three prong plug are installed upside down. The third “center prong” or “ground” is actually on the top per the original design.

Most new builds and electricians are opting to install this way now. The orientation has no impact on performance.

Except that if a plug falls out, you want it to stay grounded… meaning the ground should absolutely be on the bottom because gravity.

the ground should absolutely be on the bottom because gravity.

Not necessarily. You typically want the ground longer so it’s the first in and last out. Type G has the ground on top. I vaguely remember hearing that’s because if it comes slightly out and something sharp or metal falls on the plug, you want it to hit the ground and not the live part…but I don’t know how reliable that story is.

Some electricians started doing it since it became a viral Internet trend to intentionally drop quarters onto the prongs of a slightly pulled out plug.

In history there’s only been a few cases of a fires being started because of an accidental thing falling on the plugs. The breaker trips before a fire would start in almost all cases. Provided the breaker isn’t faulty or something. Which you should be testing regularly as a home owner.

Funny thing about that, TC recently released a video on this as well.

https://youtu.be/vNj75gJVxcE?feature=shared

TL;DW: Ground on top probably causes more problems than it would solve.

There’s patents with these features specified for locking and even modern patents reference these old patents.

Technology connections got it wrong, it happens.

“I like a snug plug” - Dusty Slay

Like the european ones still have?

https://youtu.be/udNXMAflbU8?si=vKhkE-pKhltLJ_dF

Not all of them do.

This is the first thing that came to mind. If you didn’t link it, I was lol. I love this channel.

“especially people who notice they have holes in them” ahahahhaha I love him. He’s so good, I can never tell if he’s in on the joke or not.

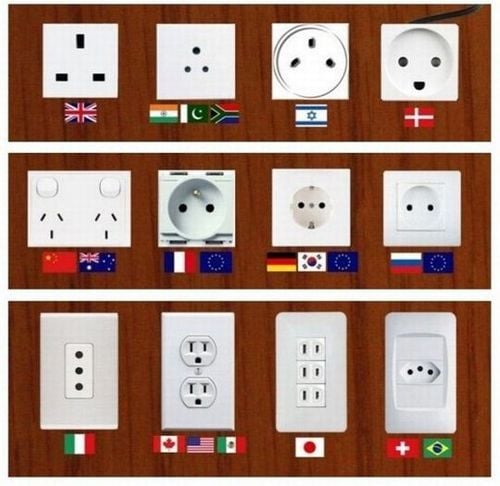

Denmark’s looks happy to supply power

I love that Danish one, always happy to see me!

USA plug skills be flipped. The ground should be on top.

Not really. Most plugs I see have ground at the bottom and there’s no official standard for orientation.

Yes, except all bulky plugs are designed for plugging into an outlet with the ground at the bottom.

No. Ground is on the bottom. Almost always. Unless it’s sideways.

Then just take it out and flip it around. It’s not hard. Just turn off the the circuit at the junction box first.

What is this, the outlet denier?

I mean, if the US is gonna steal basically everything from the UK, they might as well steal their power outlet designs since they’re that good.

Oh wait, they just started doing that by forgetting to punch holes in their own power plugs? Hmm, I wonder when they’ll make the next step.

I am prepared for the massive amount of downvotes that the Muricans will throw at me because I said that.

This is a plug for China. It will work fine in US outlets but it’s intended for that Chinese market hence the lack of holes.

While potentially true - that is not why the holes are missing.

They aren’t part of any spec.

It’s a holdover from older designs, modern receptacles hold the plug differently, older ones were designed to hug the holes to hold the plug in places.

Does China use a compatible electrical system to us?

No. 220v/50hz in china, 120v/60hz in North America.

The plugs are similar though, with china using the non-polarized and un-grounded version of the plug used in North America. (two flat blades, same width as Americas live pin) If you didn’t know better, you could plug in the wrong things in either country.

Thus what is shown can not be for China, because there is ground?

Yup, that’s a North American plug.

The grounded outlets that they do use have slanted live/neutral pins like Australia:

Taiwan actually uses the North American plug design too, but at 110v/50hz.

Some electronics may tolerate that, but many won’t function or may even be damaged by the change in frequency.

Type B looks like an ape that just got some bad news

deleted by creator

Throw it out. It’s not safe to use.

The holes don’t actually do anything. https://youtu.be/udNXMAflbU8